欢迎光临江阴市昌盛药化机械有限公司

![]() 收藏本站

收藏本站

![]() 联系我们

联系我们

欢迎光临江阴市昌盛药化机械有限公司

![]() 收藏本站

收藏本站

![]() 联系我们

联系我们

概述:

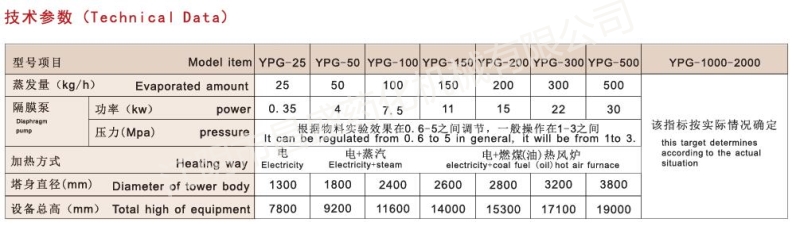

本机组是一种可以同时完成干燥和造粒的装置。按工艺要求可以调节料液泵的压力、流量、喷孔的大小,得到所需的按一定大小比例的球形颗粒。本机组工作过程为料液通过隔膜泵高压输入、喷出雾状液滴,然后同热空气并流下降大部分粉粒由塔底排料口收集,废气及其微小粉末经旋风分离器分离,废气由抽风机排出,粉末由设在旋风分离器下端的授粉筒收集,风机出口处还可装备二级除尘装置、回收率在96-98%以上。本机组与物料接触部份塔体、管道、分离器的材料,均采用SUS304制作。在塔体内部与外壳之间有足够的保温层,填充材料为超细玻璃棉,塔体设有观察门、镜、光源及控制仪表,由电器控制操作台控制和显示。本机组的热源装置采用蒸汽加热或电加热器,具有操作方便、启动快、结构紧凑、热风干净清洁等优点。另外在电气控制柜内装有电加热器的控制调节装置,使进口温度无级调节。对于缺电地区可采用蒸气加热或燃煤、燃油热风炉等方式,局部或全部代替电加热装置。本公司可以提供根据用户的实际需要的加热方式。

Descriptions:

The unit can finish granulating and drying simultaneousIy and can produce spherical granules with sizes that you need only by adjusting the pressure, the discharge rate and the jet orifice of liquid materialspump. The unit's working process: The feed liquid is pumped into the centrifugal spray atomizer on the top of the drier by diaphragm pump. ln the spray atomizer the feed liquid wilI be fully atomized and then will be dried by the heating air. Majority granules will discharge from the bottomof the drier, the residual granules and exhaust gas wiII be separated by whirlwind separator, and then the exhaust air wiIl be exhausted by blower fan and the residual granuIes will be collected by the dust catcher at the bottom of whirlwind separator. Furthermore, the blower fan is equipped with secondary dust collect unit. The recovery ratio of the unit is 96% to 98%. The unit uses SUS304 stainless plates to make tower body, pipeline and separator. Between the tower body and the shelI there is a thermalinsulation layer that employs extra fine glass wools as filling materials. The tower body is weIl equipped with observation door, sight glass, Iight source and control meters and its operation is controlled and dispIayed by the operating desk. The unituses steam heating modeor electric heating mode and is characterized by convenient operation, fast start-up, compact structureand clean hot air. Besides, the control adapter of electric heater in electric controI cabinet can provide stepless control for the inlet temperature. Custom design in heating type available.

适用范围:

喷雾干燥造粒:

化工:有机催化剂、树脂、合成洗衣粉、油脂类、硫按、染料、染料中间体、白碳黑、石墨、磷铵等。

食品:氨基酸及类似物、调味料、蛋白质、淀粉、乳制品、咖啡抽取物、鱼粉、肉精等。

制药:中成药、农药、医药冲剂等。

陶瓷:氧化镁、瓷土、各种金属氧化物、白云石等。

喷雾造粒:氧化铝、陶瓷粉、制药、重金属超硬钢、化肥、粒状洗衣粉、中成药等。

喷雾冷却造粒:胺基脂胶酸、石蜡、甘油酸脂、牛脂等。

喷雾结晶、喷雾浓缩、喷雾反应等方面也经常用到。

Application:

Spray drying and granuIating:

Chemicals: organic catalyst, resin,synthesized soap powder,oil,dyestuff,intermedium of dyestuff white carbon black, graphite and etc

Food: amino acid and anaIogue, seasoning, protein, starch, dairy products, coffee extraction, fish meal and etc.

Prepared Chinese medicine, agricultural chemicals, antibiotic, drug and etc.

Magnesia, porcelain clay, metal oxide, dolomite and etc.

Spray granulating: alumina, ceramic powder, drug, hard steel, chemical fertiIizer, granular washing powder, prepared Chinese medicine and etc.

Spray cooling and granulating: fatty acid, paraffin, gIyceric acid tallow and beef beef tallow etc.

Spray crystaIIizing: spray concentrating and spray reacting of materials.

设备特点:

干燥速度快,料液经雾化后表面积大大增加,在热风气流中,瞬间就可以蒸发95-98%的水份,完成干燥的时间仅需十几秒到数十秒种,特别适用于热敏性物料的干燥。所得产品为球状颗粒,粒度均匀,流动性好,溶解性好,产品纯度高,质量好。使用范围广,根据物料的特性;可以用热风干燥,也可以用冷风造粒,对物料的适用性强。操作简单稳定,控制方便,容易实现自动化作业。

Features:

Fast dry; 95-98% moisture can be evaporated instantaneously; only tens of seconds needed for dry; especiaIly for heat sensitive materials. Finished products have uniform granularity, good fluidity, exceptionaI dissolvability and high purity. Strong applicability for materiaIs; drying by hot air and granulating by cold air available. Easy and stable operation and convenient control.

江阴昌盛药化机械有限公司(江阴市昌盛制药机械厂),位于江阴市文林镇,东连上海、南临苏州、无锡,地处“黄金通道”之称的沪宁高速公路无锡东。本公司主营干燥机,混合机,制粒机,粉碎机等药化设备。本公司有三十年的机械制造历史、技术力量雄厚、工艺先进、设备齐全、由于生产及市场需要,本公司聘请了制药、化工、食品机械方面的多名专家及工程技术人员,发展了一系列的制药及化工机械设备,主要产品有中药粉碎机、筛粉机、混合机、制粒机、干燥机等多种系列产品,为我国的制药及化工、食品等行业的机械装备更新换代作出了一定的贡献!产品质量得到广大用户的一致好评。

热门关键词:粉碎机、粉碎机、中药粉碎机、中药粉碎机、混合机、

友情链接:无锡洗衣机维修 、

Powered by 江阴昌盛药化机械有限公司 版权所有 © 2008-2018, All right reserved 备案号:苏ICP备17021015号-1 技术支持:鼎尚网络 ![]() 苏公网安备32028102003037号

苏公网安备32028102003037号